-

AGC Chemicals Americas

-

English

English

- Customer & product inquiries: 1-800-424-7833

AFLAS® Fluoroelastomers

Material of choice for products and systems that work in tough environments and require high reliability.

AFLAS fluoroelastomer resins contain alternating polymers of tetrafluoroethylene and propylene.

AFLAS® fluoroelastomer materials are ideal for parts and components that need to perform reliably in the world’s harshest environments. AGC formulated AFLAS resins from alternating polymers of tetrafluoroethylene and propylene to achieve unique properties over a conventional FKM-type fluoroelastomer.

These properties include outstanding resistance to heat, chemicals, fuels, acids, bases, solvents, ozone and steam. Several AFLAS grades are approved by the Food and Drug Administration (FDA) for contact with food, making them an ideal material for parts like seals that are used in food processing applications where heat and/or aggressive chemicals will quickly degrade other types of rubber.

AFLAS grades

- 100 Series – high strength grade – these elastomers are ideal for applications like seals that require mechanical strength. AFLAS 150P, 100S and 100H have FDA approval for food contact in the A-H temperature range.

- 150 Series – standard grade – these elastomers are ideal for the production of extrusions and compression moldings that require electrical insulation properties

- 150E – grade for insulating high-voltage power cables

- Latex Series – liquid grade – these elastomers are ideal for binders, coating materials and other applications

- 200P – specialty FKM for improved performance at cold temperatures

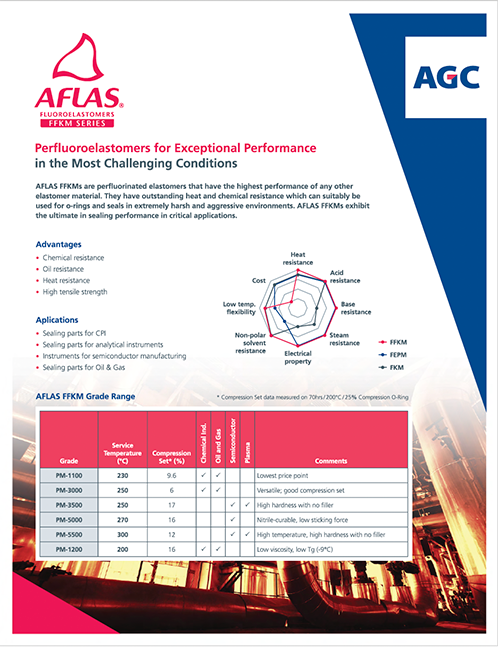

- PM-1100 and PM-3000 FFKM series – for ultra-hot temperatures

- PM-3500 FFKM series - a peroxide curable polymer that can achieve a hardness of 70 without adding fillers that increase the risk of contamination. Ideal for semiconductor etching processes when resistance to plasma is critical

- PM-5000 and 5500 FFKM series - nitrile curable polymers that have high temperature durability beyond 300 °C. Their O2 and NF3 plasma resistance make them ideal for semiconductor applications.

- 400E or 600X FEPM grades – designed for multi-layer hose constructions used in high-pressure, high-temperature areas around the engine. Resistant to NOx, SOx, engine oils and other aggressive automotive fluids.

Select AFLAS fluorinated elastomers when failure is not an option

AFLAS 100 and 150 series fluoroelastomers are easily compounded by open mill and internal mixers. These polymer compounds are then fabricated into finished parts and shapes (like “rubber” seals and gaskets) using press molding, injection molding, extrusion and calendaring processes. AFLAS parts are used in many industries including:

- Oil & Gas

- Chemical Processing

- Heavy Duty Diesel

- Automotive

- Wire & Cable

- Industrial

- Food Handling and Pharmaceutical

AFLAS 200P specialty FKM maintains good base resistance and offers improved performance at cold temperatures. AFLAS PM-1100 and PM-3000 FFKM series fluoroelastomers are peroxide-curable and hold their performance at temperatures up to 270 degrees C.

AFLAS Fluoroelastomer manufactured without PFOA. For more information, click here.

- Resistant to highly reactive organic and inorganic chemicals

- Excellent volume resistivity (greater than 1016Ω cm)

- Radiation resistance up to 200 MRad of gamma-ray radiation

- Unaffected by extended exposure to 200 °C steam

- Continuous use at 230 °C

- Resistant to highly reactive organic and inorganic chemicals

- FDA-compliant for food contact

- Parts and components of food processing equipment

- Packings and O-rings

- Engine seals and gaskets

- Wire and cable

- Shaft seals

- Thin sheet

- Oil and gear seals

- Fluoroplastic modifier

- Diaphragms

- Multi-layer laminated hoses

Click here to request an SDS sheet.

- Two Instron load frames

- Surface/volume resistivity

- Hardness

- Brittle point

- FTIR & UV/vis/Near IR

- Pressure vessel

- Color-matching

- Compression set

- Immersion testing

- Various ovens

Helpful Resources

Contact our fluoropolymer experts to discuss your specific application.

Latest from the Blog

Fluoroelastomer Rubber Performs in Demanding Applications

After selecting a fluoroelastomer, it is important to perform tests and evaluations to verify its compatibility with the application’s demands. Avoid cheaper blends with inferior qualities and consider specialized grades for heightened performance.metic and personal care manufacturers looking to enhance their products and stay competitive.

Read MoreFluoroelastomer Rubbers Produce Superior and Environmentally-Safe Seals When Bonded with Waterborne Adhesives

Fluoroelastomer rubbers, specifically AGC’s AFLAS resins, are an excellent choice for creating rubber parts and components, including seals for machinery in harsh environments.

Read MoreAFLAS® Fluoroelastomer Pre-Compounds Enhance Performance of Parts Used in Harsh Oil Recovery Conditions

Productivity and safety in oil and gas recovery operations depend on the strength of equipment, parts and systems. Downtime or injuries from equipment failure are unacceptable, so machinery must be built with parts and components that will not fail in…

Read More